There are a few different reasons your engine might make a knocking, ticking or pinging sound. Let’s break each down and talk about what might be happening.

Is it an engine knocking sound, tick or ping?

One driver’s knock is another driver’s tick. Or ping. Still others compare the engine knocking sound they hear to marbles rolling around inside a coffee can.

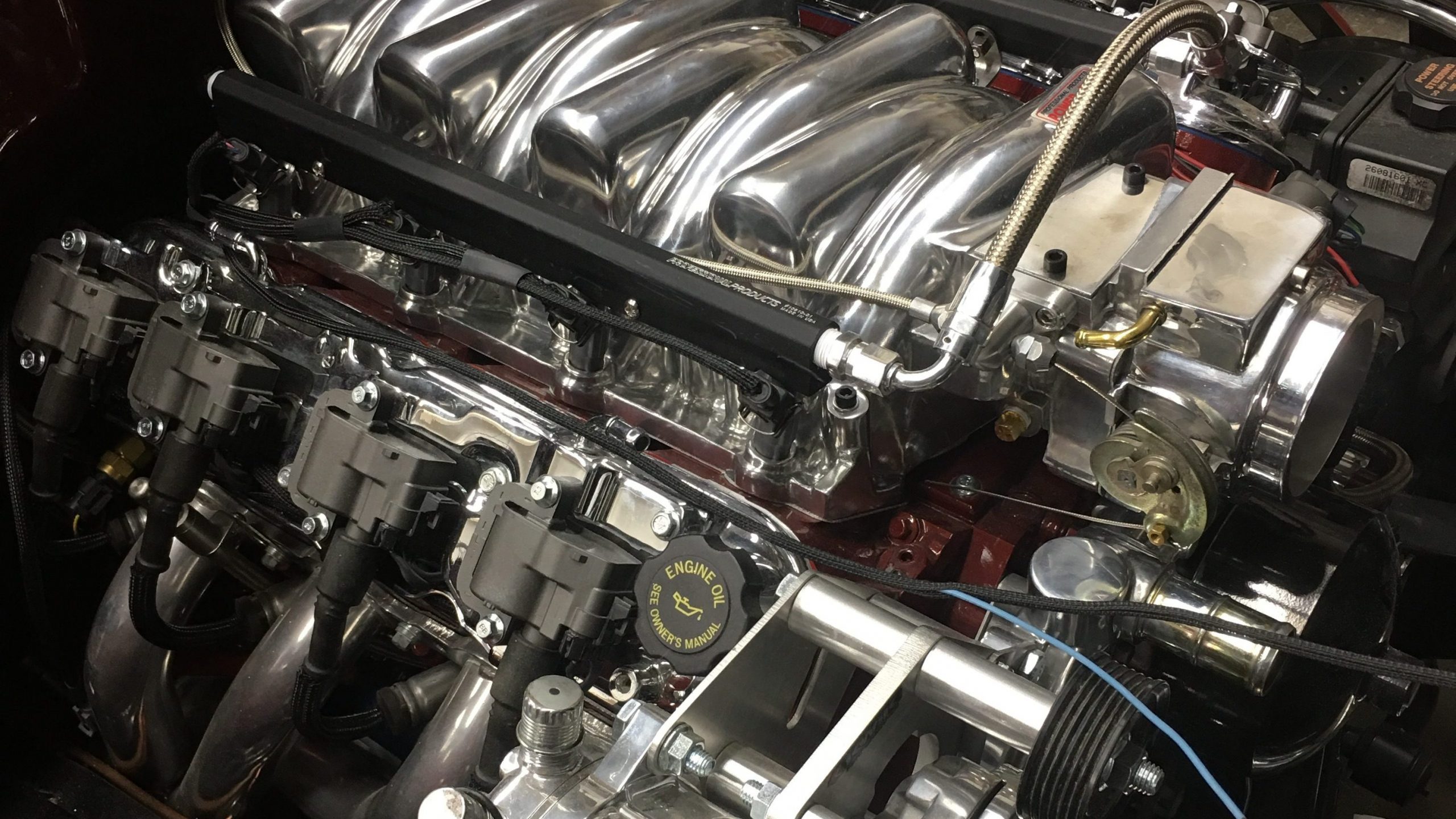

The spontaneous ignition of air/fuel inside the cylinders is a common source of engine knock.

While the description of the sound may differ, the circumstances under which it occurs are often the same – low-speed, high-torque conditions common when you’re accelerating.

How engine knock occurs

Say the clock has struck 5:00 and you make a bee-line to your truck and take off for home. When you mash the accelerator out of the parking lot, that’s when you hear an engine knocking sound. Or ping. When you let off the gas, it goes away.

This is likely due to either pre-ignition or detonation. They’re effectively the same phenomenon, but they occur at different times.

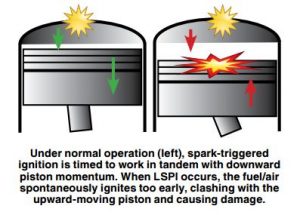

In a properly running engine, spark-triggered ignition typically occurs a few degrees before the piston reaches top dead center (TDC). This careful timing ensures the downward force of the exploding fuel/air mixture works in tandem with downward piston momentum, resulting in optimum efficiency and power.

That’s bad timing

Pre-ignition (and its cousin, low-speed pre-ignition [LSPI]) are abnormal combustion events that throw off this precise balance. Under certain conditions, the fuel/air can spontaneously ignite too early in the combustion cycle. Sometimes low-octane fuel is to blame; sometimes it’s deposits on the piston crown.

Fuel with too low an octane rating for your engine can sporadically ignite prior to the piston reaching TDC.

Or, chunks of carbon can heat up and create a hot spot that effectively ignites the fuel/air before the plug fires. Then, when the plug does fire a fraction of a second later, the two flame fronts collide. In certain conditions, they can clash with the upward-moving piston. The resulting shock wave rattles the piston inside the cylinder, creating the knock, ping or can-of-marbles sound you hear.

Detonation has the same effect, except it occurs after the plug fires.

Computers in modern vehicles can detect engine knock and compensate by adjusting engine timing. Though it saves your engine from destroying itself, performance and fuel economy can suffer.

Tick, tick, tick

Say your engine is ticking like a time bomb, especially in the morning when it’s cold. You likely have a valve-train issue.

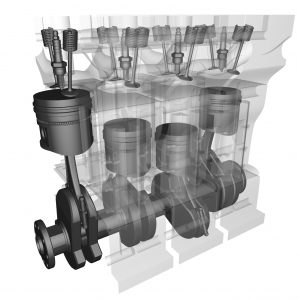

Your engine uses intake valves to feed clean air into the cylinders and exhaust valves to kick spent combustion gases out. The valves open and close thousands of time per minute in a choreographed whirlwind of activity.

A finely balanced system of parts – rocker arms, valve stems, cam lobes, lifters – control their movements. The clearances between these parts, known as lash, can become loose (or sloppy, in automobile nomenclature). When that happens, all those moving parts clattering against each other can create a ticking sound.

It’s especially noticeable in the morning before the oil has had a chance to circulate throughout the upper end of the engine.

Many engines use hydraulic lifters, which use an oil-pressure-assisted plunger and spring to compensate for lash, helping ensure the system runs smoothly and quietly.

Proper oil pressure plays a big role in valve-train operation and noise. Low oil pressure can reduce the effectiveness of hydraulic lifters, increasing lash. This is most likely to occur with a low-quality conventional oil that thins at high temperatures, preventing the engine from developing good oil pressure.

If the rods are knockin’…

Rod knock is yet another possible explanation for your engine knocking sound.

Your engine is built with a designed clearance between the crankshaft journals and the connecting rods. In a properly running engine using a good oil, the motor oil fills those clearances and prevents metal-to-metal contact.

But, let’s say you’ve been using a poor-quality conventional oil.

At high temperatures, the oil thins and the fluid film weakens. The pressure between the crank journals and connecting rods squeezes the oil from the clearances. Now, metal is riding on metal, wearing the surfaces and widening the clearances. Eventually the clearances widen so much that you begin to hear the metal surfaces clattering against each other. Eventually, they’ll weld together and destroy the engine.

Quieting a noisy engine

This all sounds dire. But you can sometimes address pre-ignition by using a higher octane gas or by cleaning deposits from your engine with a fuel-system cleaner like AMSOIL P.i. Performance Improver.

Using a higher-quality oil that flows better in cold weather and maintains its viscosity when hot can sometimes quiet a valve-train tick.

Rod knock is the worst of the three. Once the clearances between the crank journals and connecting rods have widened due to wear, it’s just a matter of time before catastrophic damage.

In any case, visit your mechanic and take care of the problem before it gets worse.

The bottom line…

The moral of the story is simply to pay a little more now to maintain your vehicle rather than spend a lot later to fix it.

Use a high-quality oil that stands up to extreme heat and maintains correct oil pressure. Periodically clean combustion chamber deposits with a fuel additive, such as AMSOIL P.i.

Doing so can help keep your vehicle running properly and quietly for years.

Updated. Originally published: June 2, 2017.

I operate a bi-fuel Lincoln Town Car with 4.6L engine on compressed natural gas (CNG) or gasoline using synthetic oil. I wanted you to know the CNG Research and Motor octane for CNG is about 120. When I use CNG with factory (gasoline) ignition timing, the drivability had 300 demerits with very poor hesitation, acceleration and fuel economy. It ran like such a dog I almost removed the CNG conversion kit. But instead I bought a timing advance electronic unit on ebay.

The rule of thumb calculation to set the increased spark advance over OEM for CNG is 120-87=33/(1.5–2)=22–33 degrees. After knock testing on the road, I was able to able to set the timing advance over OEM at 27 degrees. The timing advance unit has a maximum of 33 degrees advance over OEM. And then because CNG cleans combustion chamber deposits I was able to set the timing advance (while using gasoline) 6 degrees further ahead than OEM.

I have driven 40K miles with this setting. The performance is better than on gasoline and about 30 miles per gallon equivalent with AC off on highway which is excellent for America’s largest sedan. My octane rating and drivability training stems from the my days with DuPont (in support of lead in gasoline) and Lubrizol (in support of multifunction gasoline additives).

When a vehicle is brand new there are no combustion chamber deposits requiring only 82-84 R+M/2. Then when engine deposits increase the octane requirement increases to 87. Then as your article suggests, the knock sensor will automatically adjust engine timing to keep the engine from knocking. In these modern engines if the knock sensor has to retard ignition timing then the performance, fuel economy and heat generated will increase. But my supercharged Mercedes runs fine on regular as long as I use it around town and don’t floor it.

I owe my thanks for years of on the job training to DuPont (back in the days of lead in gasoline) and Lubrizol (in support of multifunctional gasoline additives and oil additives which are required today).

Fred Pierce-Ruhland MS Chemical Engineer PSU’70

Sorry correction to the calculation in my previous reply. The “rule of thumb” calculation should equal 16.5 to 22 degrees. In my particular engine I was able to set it to 27 degrees advance without audible engine knock. Also when I told the timing advance manufacturer he advised to use a lower timing advance setting to be more conservative. I experimented with 15-33 degrees advance before settling on 27. Peak performance is obtained at 2-3 degrees below the ignition setting for trace knock. It is important to be able to briefly hear trace knock and then back off to set it properly. Also there can be differences in CNG octane quality, in the sound insulation of the engine compartment and also the hearing ability all of which can affect the observed octane rating. True I pushed the envelope for maximum performance at my skill level but then most of your readers will know the risk and rewards. I definitely wanted to avoid overheating catalysts and exhaust valves with a late burning CNG at factory ignition timing.

PS: I run Amsoil Synthethic 100 Compressor oil in my Bauer CNG 3600PSG compressor. I’ll be ordering some soon.

Hi Fred,

You clearly know your stuff. Thanks for sharing, and thanks for reading.

John

Quality synthetic oil will go a long way in preserving the life of any engine and regular oil changes will protect your engine even better. Some knocks should not be ignored they can indicate failure whether oil-related or not. So if your engines knockin’ it may

soon be stoppin’.

First ,you guys know your stuff ,second ,all I can say is that I’ve been using amsoil in my harleys for years ,the shovelheads ran great ,and so far I’m on my 5th Silverado 2009 ,and from day one that’s all I’ve ever ran , I’m no sales man’s, I think it’s great stuff , retired ibew member from Philadelphia pa

You can add piston slap to the list also. Have a 2000 Silverado 5.3. Very common issue from 2000 to 2003. GM gave 100k extended warranty back then if pressed, mine not serious, quiets after a few moments when cold, short skirted pistons or not checking each piston to cylinder bore clearance to blame? Thanks.

Tom