Here at AMSOIL, we’re always investigating ways to help you get the most out of your vehicles and equipment. One example includes zero-turn mowers used by landscape professionals and homeowners with big yards to maintain. In this post, we’ll review some zero-turn mower maintenance best practices.

How zero-turn mowers work

Zero-turn mowers have been a staple for landscape professionals for several years and are popular among homeowners with large lawns. Their advantage comes from the ability to make sharp turns with swiveling front wheels and independent rear wheels.

The machine is typically controlled by a series of belts, pulleys and hydraulic controls that the user operates with control levers. They cut closely along the edges of shrubs, flowerbeds and other obstacles, decreasing the need for extra trimming.

They’re especially convenient when mowing around trees and making 90-degree turns since you don’t have to engage the clutch several times to go backward and forward, saving time and making the job easier.

Zero-turn mower safety

Zero-turn mowers do have downsides. Steep slopes are a hazard, and many manufacturers warn about potential rollover risk. As a best practice, consult your owner’s manual when dealing with slopes more than 10 degrees, especially if the grass is wet. Many models have roll bars and seat belts to help prevent injury.

Avoid side mowing, especially if there’s standing water or a drop-off at the bottom of the slope. In these cases, a push mower or trimmer is likely the best way to go. As always, it’s best to use proper hearing and eye protection.

Zero-turn mower maintenance

A properly maintained zero-turn mower can deliver years of reliability, even after having logged several hundred hours.

Here are a few maintenance tips:

Maintain zero-turn mower belts

Belts are one of the biggest maintenance concerns with zero-turn mowers. To keep the belts working well, keep the outside of the deck clean and periodically clean the underside of the deck of clippings and debris. Keeping the deck clear will help prevent the belts from getting beat up.

Consider coating the deck and blade with AMSOIL Heavy Duty Metal Protector to keep out water and dirt. Be sure to periodically check the pulleys and belts for wear and replace them as needed.

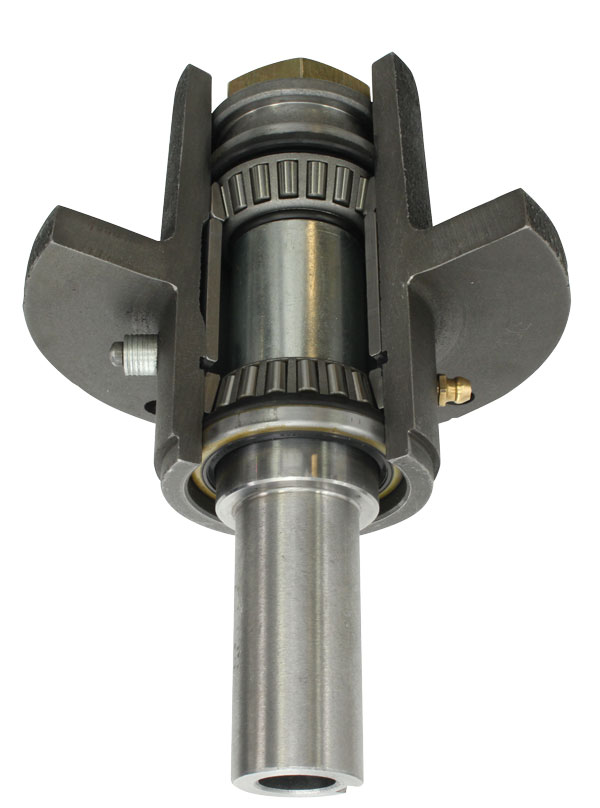

Grease the spindles

Spindles are another component that needs attention. Commercial-grade zero-turn mowers often require proper greasing of the spindles to ensure the blades rotate properly.

Grease spindles using AMSOIL Synthetic Water-Resistant Grease to protect against metal-to-metal contact and resist washout in wet conditions, reducing the need for frequent greasing.

Tend the transmission

Many commercial-grade zero-turn mowers also use a hydraulic transmission that uses oil pressure to drive the wheels in different directions and at variable speeds. Heat exposure leads to sludge and varnish formation that degrades performance, resulting in rough operation and poor control that frustrates operators and leads to hydrostatic transmission wear and expensive repairs.

To ensure smooth operation, change transmission oil according to manufacturer recommendations. Some models may specify a motor oil to keep these high-pressure components protected. AMSOIL 20W-50 Synthetic Hydrostatic Transmission Fluid is excellent in these applications.

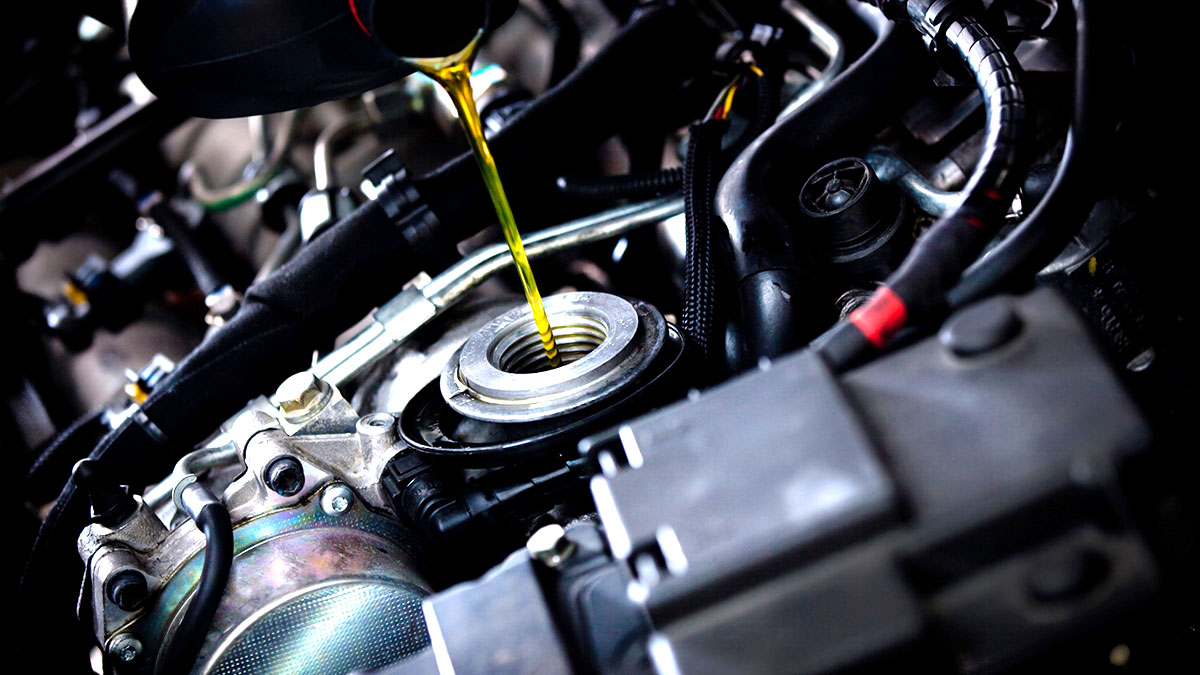

Change the oil

Landscaping professionals put a lot of hours on their equipment, which requires regular fluid checks to ensure it performs at its best and gets the job done when called upon. When it’s time to change the oil, premium AMSOIL synthetic motor oils provide the protection your equipment needs to keep it running at peak performance. It is also a good idea to change the oil at the end of the season, so contaminants are flushed from the engine before it is parked.

Storage

When the off-season comes, be sure to clean and protect your investment and add fuel stabilizer to ensure it fires up quickly when removed from storage next season. For more storage tips, check out the video below.

Amsoil is the only thing I’ve put in anything with a gas motor over the last 2 years. Including my ZT mower, my snowmobiles, my family vehicles, and even my ice auger for fishing. Unparalleled IMO

For the Hydraulic system, Hustler recommends 10 W 40 with high zinc in my zero turn mower which is a 602 D slope mower.

In my 2013 SCAG Freedom Z 52″ cut w/Briggs & Stratton 27HP Commercial engine, I run AMSOIL 10W-30 Signature Series Motor Oil. I chose it over the Formula 4-stroke because of the higher TBN. I also found that the EaO34 Oil Filter fits. I use it for the slightly increased Oil capacity. In the Hydrodrive (hydraulics/transmission) I run AMSOIL Premium Protection 20W-50 and 2 Ea15K09 Oil Filters which fit this model. Finally, I always run Quickshot at the rate of 4 Oz. per 5 Gal. of Gas + 6 Oz. Octane Boost in full 6-1/2 Gal. Tank. In the fall at the end of the season, I change all the Oils & Filters so it’s ready to go the following spring.

My SCAG easily outperforms every other Mower in my neighborhood & I’m sure it will last for decades being protected by AMSOIL throughout!

We own a water cooled diesel zero turn riding mower and use a backpack blower to clean the deck pulley area, the radiator, and the hydro oil heat exchanger/cooler after every use. Takes about 10 seconds I tend to think that this routine has helped the belts and pulleys last longer I also use AMS oil grease on the spindles and the chassis. No issues with 1900 hrs

Bruce D.

Dealer in NJ

I love gardening, and I can spend all of my free time taking care of my garden and discuss about gardening experiences with my friends, who have the same hobby as me. That is the reason why I would like to create My Greenery Life as a useful blog about gardening and lawn care.

UPDATE: I switched the Hydrodrive to AMSOIL 20W-50 Synthetic Hydrostatic Transmission Fluid (AHF) when AMSOIL introduced it. I believe that my SCAG’s Hydrostatic system runs even cooler than before. Thank you AMSOIL!